I’m excited to share with you another DIY bathroom floating vanity build! It is a small floating vanity that comes with a drawer with a cutout for plumbings, making it super easy to storage things and take things out. I also added a tip out tray on the top right in front of the bathroom sink to provide additional storage such as toothbrush, toothpaste, etc.

If you have a small bathroom and look to add storage, this DIY floating vanity project is for you. It features a 30” wide floating bathroom vanity, and we placed it in the bathroom of our guest room which also doubles as a home office for my husband.

I’ve simplified the DIY process this time around and even incorporated a new drawer style that’s easier to build than the shaker style I used in my previous build. I’m thrilled with how this vanity turned out, and I can’t wait to share all the details with you.

So, grab your tools and let’s get started on this build!

Materials I used for DIY Small Floating Vanity for Bathroom:

- 1/2 in PureBond Maple Plywood

- 3/4 in PureBond Birch Plywood

- Birch Wood Veneer

- Wood Glue

- Wood Putty

- 1 ¼” Pocket Screws

- 1 ¼” Brad Nails

- Wood trim piece

- All-Purpose Primer

- Paint (Benjamin Moore Advanced Line in Spellbound)

Tools I used for DIY Small Floating Vanity for Bathroom:

Note: you don’t need to own every single tool to make this project. Use what you have and invest in tools that you’ll be able to use again for your future DIYs.

- Table saw

- Jigsaw

- Edge Banding Trimmer

- Mitre Corner Clamp

- Pocket Hole Clamp

- Long Bar Clamp

- Right Angle drill tool

- Side-Mount Slide Set

- Self-Centering Drill Bit

- Power Drill

DIY Small Floating Bathroom Vanity Building Plans:

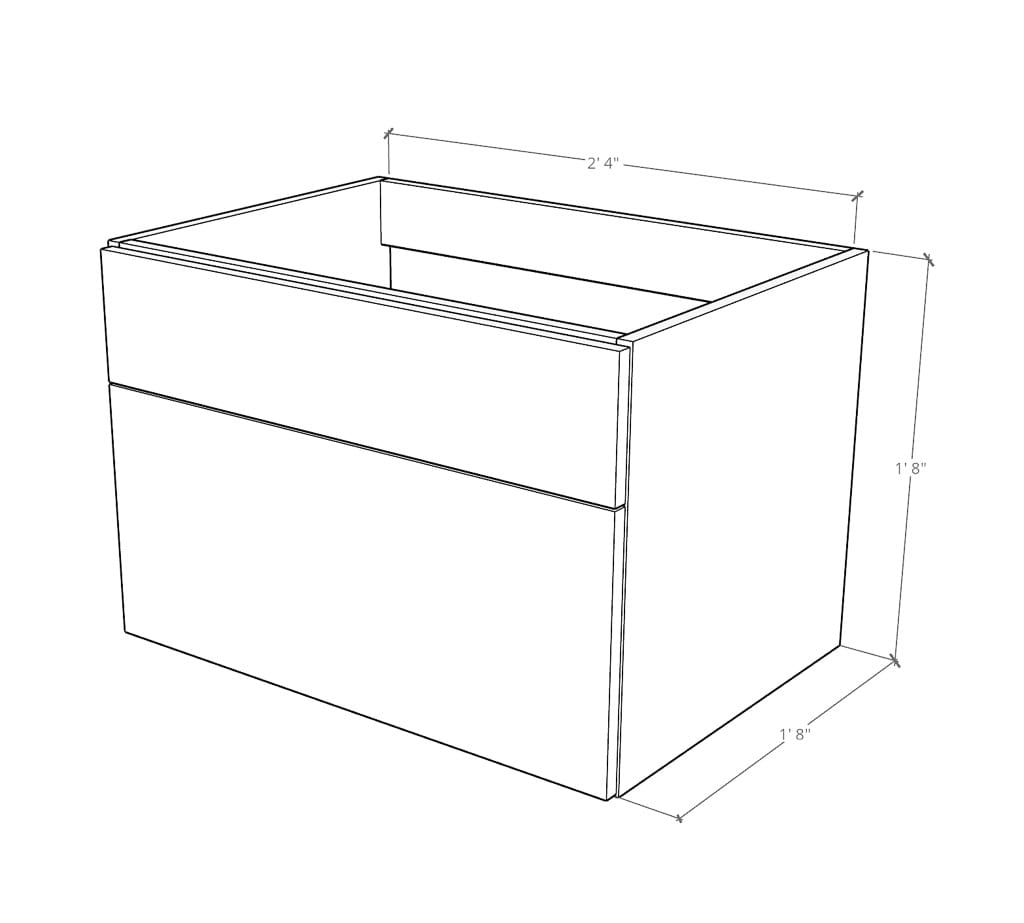

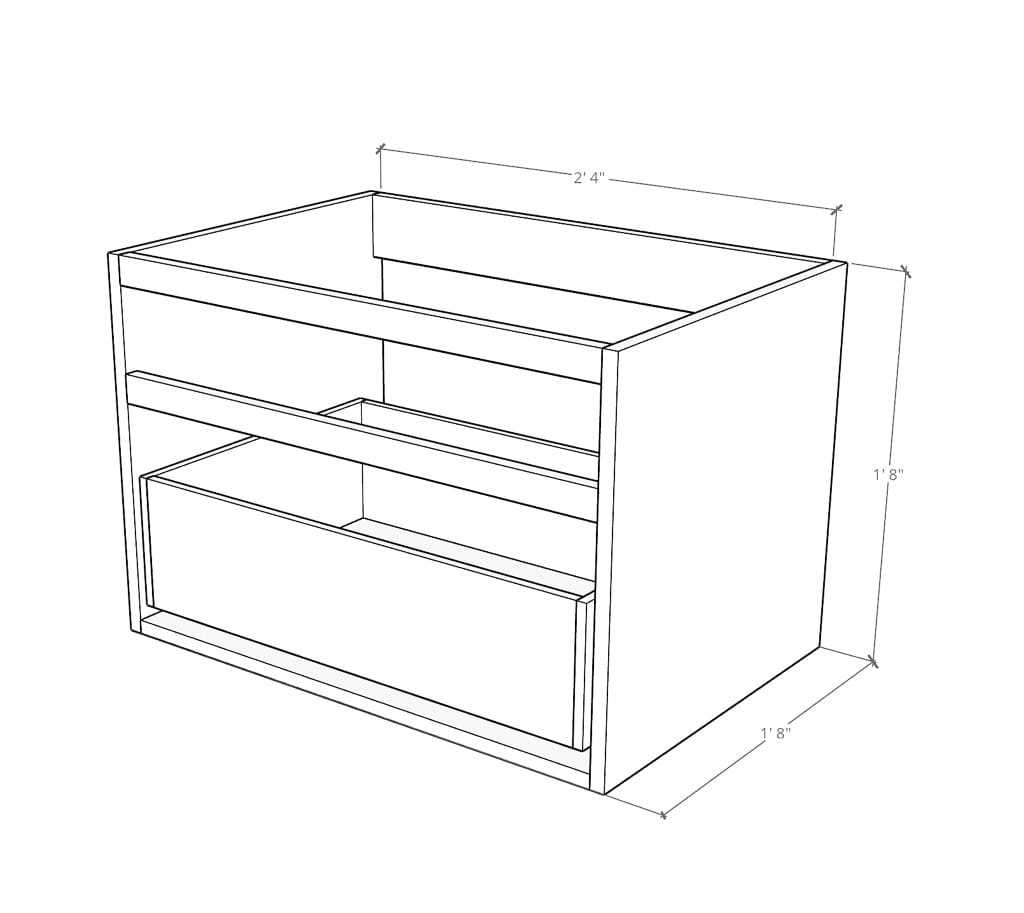

Here’s a building plan and 3D model for the DIY floating vanity. It’s 30 inches wide, 20 inches tall, and 20 inches deep, plus the thickness of the drawer fronts.

I added a drawer inside to make things more accessible, as well as a tip-out tray on the top as extra storage for other knick-knacks.

DIY Small Bathroom Vanity Video:

If you are a visual learner like me, I’ve made this video with the entire DIY process. I recommend you to watch it though to understand the process, and use the written steps below for detailed instruction.

How to Build a Floating Bathroom Vanity

Step 1: Plan the cut list and cut out all pieces

For the boards, I used 3/4 inch high-quality plywood. You want to choose cabinet grade plywood because they are more durable and the surface is smooth.

I’m planning to paint them later, so I chose birch finish as the wood grain since it’s not very obvious and the surface is more smooth than other types of plywood such as oak.

Before cutting out any pieces, it is always a good idea to plan out everything you need, and optimize them with a cut list.

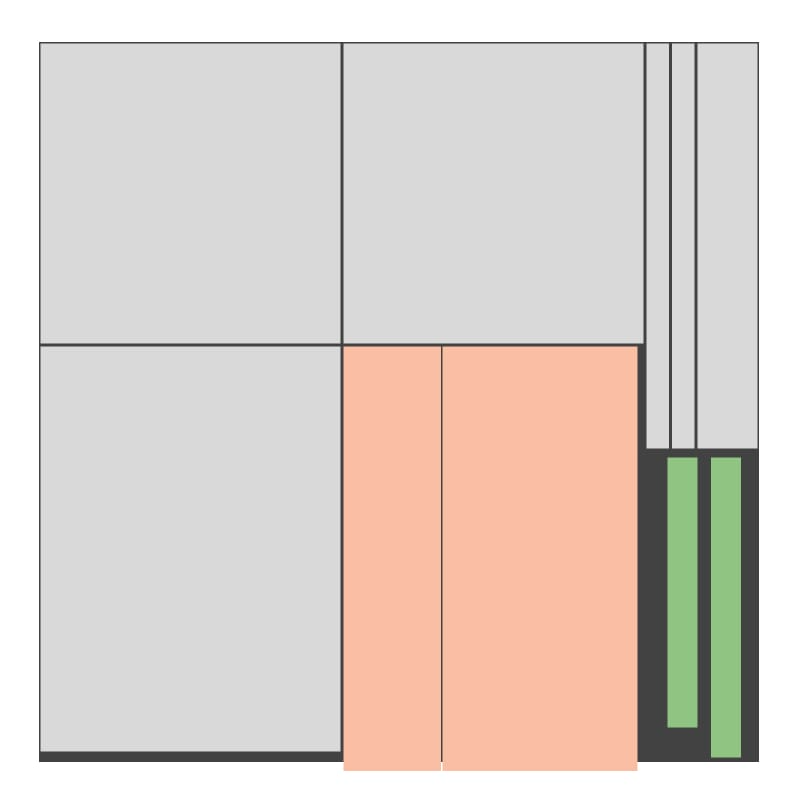

This will make it easier when you are in the cutting phase, since you don’t have to stop and measure each time you cut a piece. I laid out all the pieces I needed for this vanity box, which were a little larger than 4×4 plywood, including pieces for the frame and drawer fronts.

My vanity DIY cutlist: The orange pieces are the drawer fronts and the green pieces are the trims that I used to install between the floating vanity and one wall, to make sure my drawer can open properly. I planned to add trim pieces to both the side and the bottom, then my builder persuaded me to only install the side trim.

Then I just used my table saw to rip all the pieces. I found it easier to rip into stripes of the right depth first, which is 20” in this case, then cut those pieces to their corresponding length.

After cutting, I recommend you mark them using painter’s tape or write on the edge with a pencil, to keep track of them. I also lightly sand the edge if they turn out to be a bit rough to handle.

For the drawer box, I used 1/2” plywood, also in cabinet grade, which I’ll share in later steps.

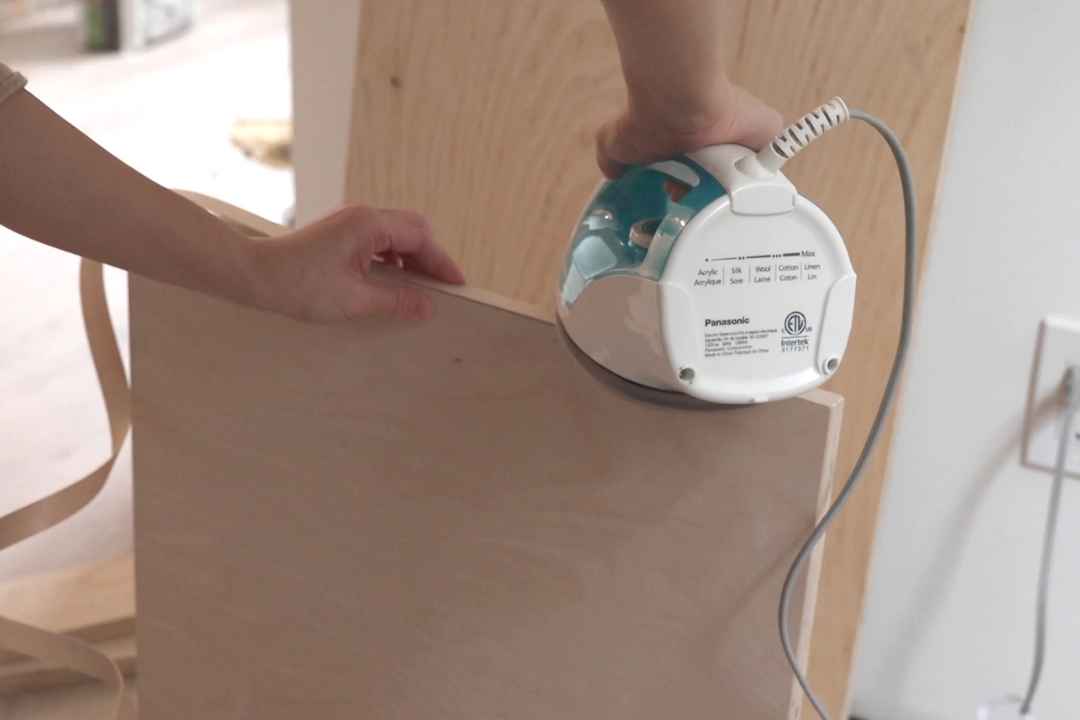

Step 2: Conceal the edges

To conceal the unfinished plywood edge which is not so pretty, I used wood veneer. This is a very cheap way to cover any plywood and make it look like one piece of wood.

I don’t use real wood for cabinet construction because it’s a less stable material as it contains more moisture, and it’s a lot harder to buy a large sheet of wood without joining them together somehow. Plywood is the best way for cabinet construction and the most cost effective, in my opinion.

Keep in mind that the wood veneers are generally slightly larger than the plywood thickness, so you need to trim the excess.

For that I used a handy Edge Trimmer, which really makes my life a lot easier. All you need to do is squeeze the tool and pass it through, and it’ll shave off those extra bits very easily.

To finish it off, you can use a hard surface (like a screwdriver handle) to burnish it, or you can lightly sand it with a sanding sponge, like I did.

Step 3: Join the pieces together to form a vanity box

To join the pieces together to form a cabinet frame, I used pocket holes. Pocket hole connections are more hidden and offer a stronger bond.

I drilled three pocket holes on each side for the bottom piece so it will be hidden once installed (unless you’re staring at them by laying on the floor!).

First I joined two sides and the bottom pieces together. I like to use long bar clamps to hold everything tight. I used 36” bar clamps for this!

Then I drove the pocket screws through those holes to connect them together. I did that without wood glue this time, but you can feel free to add glue. Having wood glue between joints can reinforce the bond, but on the flip side, if you make a mistake, it is a lot harder to undo.

Once I constructed this “U” shape, I added some braces on the front and the back.

I only need one piece on the back that will hold the cabinet box in shape plus being used as a board to install the vanity to the wall. So I started with the back and created two pocket holes on each side to connect it to the side pieces. The height of the back panel is flexible, as long as it doesn’t block plumbing coming from the wall. I did 4”.

And then I did the same with the front size. For the front, I added two pieces because I wanted to have two drawers that are in an overlay style, which means I’ll need a board between those two drawers.

This is what the vanity frame should look like after construction:

At this point, I also fill in any visible seams on the front with wood putty and sand it smooth, to achieve a smooth and seamless look when I paint them later on. If you are keeping the wood grain, there’s no need for this extra step.

Step 5: Making the drawer

Now that the box is done, it’s time to start making the drawer! I like making drawers for my vanity because they are so functional. It is a lot easier to throw random things in a drawer and still find them easily.

For my double vanity video, I did traditional construction by sliding quarter-inch plywood into the drawer box. This time, I’m doing something a little simpler.

First of all, I figured out how my drawers would piece together, and I found that it’s best to use a 2D diagram to figure out the measurements.

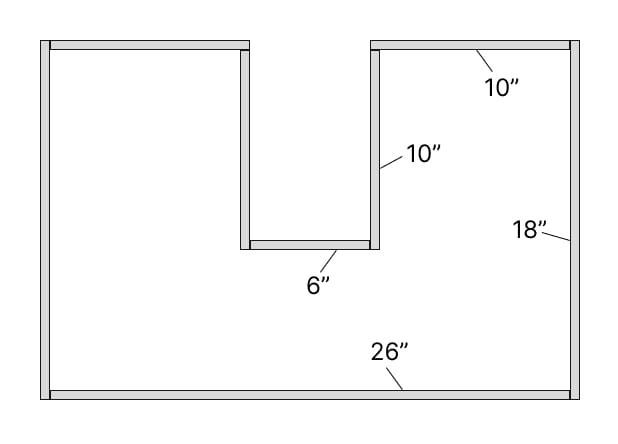

Here’s the diagram of how my bathroom vanity drawer pieces itself together with a U cutout for plumbing:

The drawer is 1” narrower than the opening width, and I used half-inch plywood for the pieces, so the math is pretty straight forward. I’m also making this drawer 5 inches high.

Later, I noticed it appears to be ½” higher for the bottom edge of faucet plumbings, so make sure to check yours before determining the height!

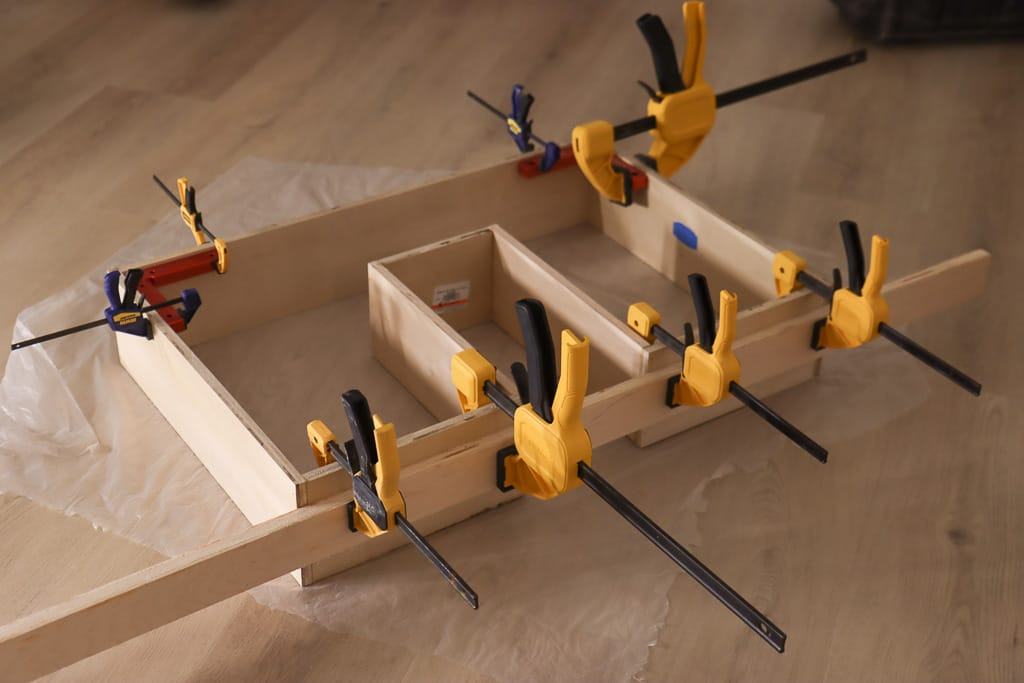

Once I have all the drawer pieces cut except for the bottom piece, I place them together, making sure everything is square.

As you can see in this photo, I marked their measurements with blue tape, since there are so many pieces.

After confirming all the plywood panels fit together nicely, I start installing them from the inside out, which is my recommended way since it gives my brad nailer some space to maneuver.

I apply wood glue and clamp them together, and then I just tap the brad nails into them. I used 1 ¼ inch brad nails. I would recommend using at least that length for up to 1 ½”.

The length of your brad nail is really important. If your brad nail is too long, it runs the risk of sticking out from the side; if it’s too short, then it doesn’t go in enough to build a strong connection. So make sure you get it right!

Once I secured the entire parameter, I clamped some straight squares just to make sure everything was at the right angle. This is important because of the U-shape of the drawer.

For the back, which is where the plumbing cut out is, I clamped a long piece of plywood just to make sure everything stays in a straight line. If it’s not straight, you run the risk of the drawer not fitting well in the drawer slides later.

After all of that, I just let them sit overnight for the glue to cure.

Step 6: Cut the bottom piece for the drawer

Now it’s time to create the bottom of the drawer. I put a half-inch plywood below the entire drawer piece from Step 5 and then traced the shape onto it so that I can cut it, and it will fit exactly inside!

I first cut the bottom piece to size, then used my jigsaw to cut the notch. Then I just pushed the bottom piece from the top all the way through to the bottom of the drawer, and now it’s ready to be secured.

Because the jigsaw is a bit harder to cut accurately, there’s a chance that you’ll have small holes. But don’t worry – you could use some small trim pieces to fill the gaps, which is what I did. The trim pieces I used are 1/16” or ⅛” ripped plywood by table saw.

And then I propped the whole thing up to make it a little bit easier to drive the brad nails, and then I nailed the entire parameter.

For the 2 sides on the U cutout, it’s a bit harder to fit a brad nailer in, which is why I used this right angle drill tool to drive two screws on each side. This is optional, so if you don’t plan on storing anything very heavy, it might be okay to just leave it out.

And your drawer is done! You can choose to paint the drawer box, or add a few layers of polyurethane (I prefer water based).

Step 7: Create the drawer front

Now let’s move on to creating the drawer front for the drawers – something that makes a big impact on the look of your bathroom vanity.

For this time, I decided to create a skinny shaker style drawer front for this bathroom vanity build. Some people may also call it pencil shaker style.

With my hack, this style is a lot easier to create than the traditional shaker style, because all you would need to do is add the wood trim pieces on the front parameter.

I’m using this wood trim piece that I found at my local hardware store, and it’s quite affordable. I cut them at 45 degrees so that they can form a picture frame and outline the 2 drawer panels. I cut out the drawer front panels at the same time as the vanity box—since they are made of the same ¾” plywood—and edge banded them at the same time.

To cut the skinny shaker trim pieces, I found it easier to make a light cut on the top first instead of cutting all the way through. Then I would just do another cut to slowly grind it down. So I did a light cut, another light cut, then cut it through. If you cut it in one go, it may fly out, which is not very safe.

Once I cut all eight pieces for my two drawers, I just arranged them in place to do a final check, then applied wood glue on the back of them and secured them with brad nails.

For this time, make sure to use a shorter brad nail, like ½” or 5/8”.

If you don’t like brad nails and the holes they create, you could also use clamps to hold them down while waiting for the glue to dry, but it will take a lot of clamps.

I used some clamps to hold down some stubborn curves because some trim pieces are not perfectly straight.

When all the pieces were secured and the wood had dried overnight, I used wood putty to fill any gaps in the miter corner and the nail holes, and then sanded it smooth.

Because there is a tiny seam between the trim piece and the drawer front panel, I ran a bead of caulk to conceal the gap.

And now we’re ready to paint!

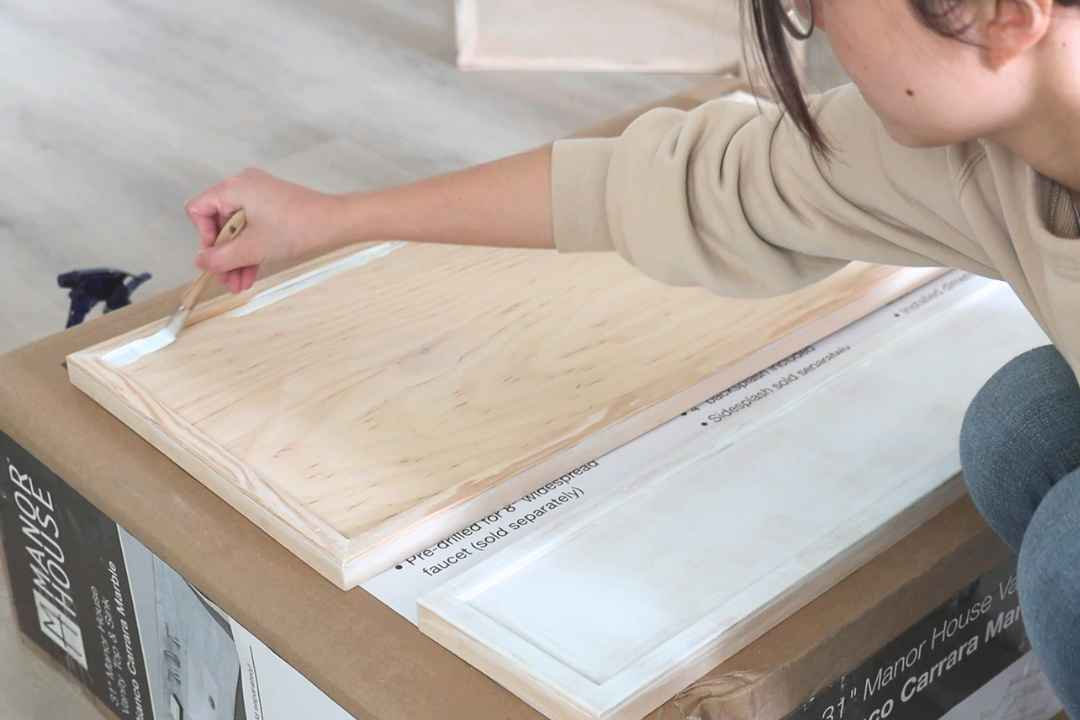

Step 8: Prime and paint!

For the vanity cabinet frame, I primed every side that will be facing out, which includes front, bottom and one side that is not attached to the wall.

And as for the drawer fronts, I primed everything including the inside. I first brushed over the edges and the corners and then used a roller to apply the primer.

After the primer dried, I gave it a light sand and applied two coats of cabinet-grade paint.

I used paint from the Benjamin Moore Advanced Line in the color Spellbound, which is a beautiful grayish-blue color. I chose this blue to match the wallpaper of my bathroom. It will also be the trim color for that space.

When I was painting the vanity frame, I also used paint to cover those small ledges that can be seen by opening the drawer.

Step 9: Install the top drawer front and tip-out tray

Now we can install the two front pieces to the cabinet!

First, I positioned them in place using a stack of poker cards, which I find are a great tool to create perfect spacing. The spacing I chose is ⅛”.

Then I traced the frame opening to the back of these front pieces with a pencil, so I know where to place it afterwards.

Since I’m using a tip-out tray template, I also marked where the overlap is. Then I removed the fronts and got ready to install!

I started with installing the tip-out tray. I used the template that comes with it and I marked all the holes where the screws will go, and drilled pilot holes after.

I also used the smaller template that it came with to mark the screw holes for the front, and installed the hardware to the front panel.

Then I brought the whole thing to the frame and just installed it to the holes I had pre-drilled.

With the template, it was actually quite easy to install, especially when you have access from the top.

Last time, I had to really put myself inside the vanity box to install this, which was a bit painful!

Step 10: Install the drawer box and the drawer front

Moving on to the drawer. This time for the drawer slides, I used a pair of 18” side-mount slide set. I mostly followed the instructions for this one but will share what I did below. You can also find the product instructions here.

After separating the drawer member and cabinet member from each side, I started with attaching the drawer member to my drawer box by marking 1 ¼” from the bottom of the drawer, then I aligned the top of the drawer member to this marked line. I installed three screws on each side using a power drill.

Since installing drawer slides can be a delicate operation, I recommend using a self-centering drill bit to create pilot holes; it’s really convenient in this situation and prevents the drill bit from sliding and creating a hole that’s not at the exact location.

Then I installed the cabinet member to the vanity frame. The instruction looks a bit complex since there are a few calculations and steps involved. In my case, I just want to install the drawer close to the bottom of the cabinet so:

- The drawer won’t get in the way of plumbings.

- I can provide ample space on the top to store anything that’s tall.

If you install the drawer member to the right location per previous step, the drawer box can be installed all the way down with a minimum ⅛” clearance from the bottom.

I just used a handy ¼” inch trim piece to lay flat on the bottom frame and placed the cabinet member on top of that. That gives me ¼” clearance, right above ⅛” minimum.

Also remember to leave 1/16” gap from the front of the cabinet opening. Then I used some clamps to hold the cabinet member in place and do the usual stuff – drill pilot holes and drive 3 screws!

Btw, I made sure not to over-drive the screws, as I followed up with a hand screwdriver to do some final turning, which gave me more control on how tight I wanted to be.

And now all that’s left to do is just push the drawer inside the box, and it worked pretty well!

Next I concealed everything with the pretty drawer front I made earlier.

To install the drawer front, I put it back in place and added again the same amount of poker cards to prop it up so that it’s in the right location and so I could match the markings on the back.

Then I drilled pilot holes from the back, making sure not to drill too deep because then it can come out from the front. You can use painter’s tape to mark the right depth on your drill bit.

And then I just drove screws from the drawer box to the front piece. I recommend doing at least four screws if your cabinet is as wide as mine, which is 30 inches wide.

DIY Bathroom Vanity Finished Project

Once I installed all the fronts, I double checked to make sure everything worked well, and installed the jewelry of cabinets – the hardware.

I bought 2 black drawer pulls from IKEA and installed them at the center of each drawer. They are in matte black finish and match my light fixture pretty well.

And now the DIY Small Floating Vanity for the Bathroom is done!

It is now installed in the bathroom of our guest/home office space! I love how much storage I was able to add with this vanity even for a small space.

In addition to the small footprint, this bathroom space is quite tricky; we have a concrete foundation sticking out 6 inches above the ground. But by making a floating vanity, we were able to make everything work!

I also like showing the floor a bit more to make the small space feel more open.

DIY Small Floating Vanity for Bathroom Summary

I really enjoyed doing this DIY project for our guest bathroom, and it has really elevated the look and feel of the space!

I hope you also have fun working on your own DIY bathroom vanity, and if you have any questions, feel free to comment below so I can help you out.

And who knows, maybe your guests will be so impressed with your new floating vanity that they’ll never want to leave! Happy building!

More DIY for bathrooms

DIY master bathroom double vanity

How to build a storage shelf above toilet

How to lengthen a shower curtain for a luxe look

Pin it for later

Leave a Reply